No.84 Huantaibei Road, Wangtai, Huangdao ,Qingdao ,China +8615563929266 [email protected]

|

Model

|

Size L*W(mm)

|

Membrane area(㎡)

|

Water amount(㎡)

|

(NTU)water turbidity

|

(mg/l)ss

|

|

FPA1

|

810*525

|

8

|

1.0~1.2

|

<1

|

<10

|

|

FPA2

|

1050*525

|

10

|

12~1 5

|

<1

|

<10

|

|

FPA3

|

1050*535

|

16

|

2.0~2.5

|

<1

|

<10

|

|

item

|

value

|

|

Condition

|

New

|

|

Applicable Industries

|

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms,

Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other,

Advertising Company

|

|

Showroom Location

|

South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Core Components

|

Engine, Motor, PLC

|

|

Place of Origin

|

Shandong,China

|

|

Brand Name

|

Spark

|

|

Material

|

Wooden case

|

|

Weight

|

According to your order

|

|

Size

|

According to your order

|

|

Power

|

0.5

|

|

Warranty

|

1 Year

|

|

Productivity

|

1000L/Hour

|

|

Weight (KG)

|

800kg

|

|

Product name

|

UF Membrane

|

|

Material

|

SS316L

|

|

Application

|

Water Purification

|

|

Type

|

Pure Water Treatment System

|

|

Certification

|

CE Certificate

|

|

Keywords

|

Waste Water Treatmnet

|

1. Pretreatment Stage

Qingdao EVU Environmental & Engineering Equipment CO., Ltd. (QDEVU) as the leading water, wastewater and sewage treatment manufacturer with over 20 years solid experience to provide productive solution to different type of water issue. Since founded in 1999, Qingdao EVU cooperated with EVU GmbH,with service offices overseas ensures the highest level of operational support for our clients. Our end to end water systems and solutions include design, manufacturing, installation, commissioning, operation and ongoing equipment maintenance. QDEVU Water has developed a reputation for delivering superior service and high performing systems, enabling its clients to reduce operating costs and extend equipment life-cycles. All EVU Water products are manufactured under the controls that conforms to the CE, ISO9001, ISO14001, ISO45001 standards,the company was certificated by BV and SGS, and own the "QDEVU" trademark certification.

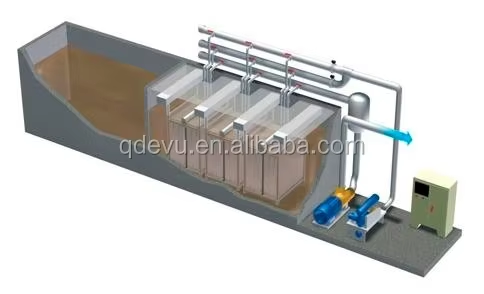

Q1: What does MBR stand for?

A: MBR = Membrane Bio-Reactor. It combines biological wastewater treatment with ultrafiltration membranes for superior effluent quality.

Q2: How does MBR differ from conventional activated sludge?

A: Our MBR replaces secondary clarifiers with 0.1μm membranes, achieving 10x higher MLSS concentrations and producing reusable water (≤5 NTU turbidity).

Q3: What contaminants can MBR remove?

A: Removes 99.9% bacteria, 95%+ viruses, 100% suspended solids, and reduces COD/BOD by 90-98%. Ideal for nutrient (N/P) removal when paired with anaerobic zones.

Q4: How often do membranes need replacement?

A: Typical service life = 5-8 years with proper maintenance. Our PVDF membranes feature reinforced fibers resisting abrasion and chemical degradation.

Q5: Is chemical cleaning required?

A: Automated CIP (Clean-in-Place) every 3-6 months using <0.5% NaOCl/CA solution. Daily backwashing maintains permeability.

Q6: Can MBR handle industrial wastewater?

A: Yes. Our membranes tolerate pH 2-12, temperatures up to 40°C, and 5000ppm TDS. Special coatings available for oil/grease resistance.

Q7: What’s the energy consumption?

A: 0.4-0.7 kWh/m³ with our optimized aeration system – 30% more efficient than standard coarse bubble systems.

Q8: How much space does an MBR system require?

A: 50% smaller footprint vs traditional plants. Modular designs allow vertical stacking for space-constrained sites.

Q9: Is the effluent suitable for reuse?

A: Yes. Meets ISO 30500 reuse standards for irrigation, cooling towers, and toilet flushing. Optional UV/ozone for potable-grade water.

Q10: What technical support do you provide?

A: 24/7 remote monitoring + on-site commissioning. All systems include 2-year performance warranty and membrane integrity guarantees.