No.84 Huantaibei Road, Wangtai, Huangdao ,Qingdao ,China +8615563929266 [email protected]

|

Model No.

|

Treat Capacity

|

Dimension

|

Power of Boost Pump

|

Power of Air Compressor

|

Total Power

|

|

WQP-5

|

5m3/h

|

3.0x1.0x1.2m

|

1.1kw

|

--

|

1.5kw

|

|

WQP-10

|

10m3/h

|

3.5x1.2x1.5m

|

1.5kw

|

--

|

1.9kw

|

|

WQP-20

|

20m3/h

|

5.0x1.5x1.5m

|

3.0kw

|

--

|

3.4kw

|

|

WQP-30

|

30m3/h

|

6.0x1.8x2.0m

|

4.0kw

|

--

|

4.4kw

|

|

WQP-50

|

50m3/h

|

7.0x2.0x2.0m

|

7.5kw

|

3.0kw

|

11.12kw

|

|

WQP-70

|

70m3/h

|

9.0x2.0x2.0m

|

7.5kw

|

3.0kw

|

11.5kw

|

|

WQP-80

|

80m3/h

|

9.5x2.5x2.0m

|

7.5kw

|

4.0kw

|

14.1kw

|

|

WQP-100

|

100m3/h

|

12.0x2.5x2.0m

|

11.0kw

|

4.0kw

|

17.6kw

|

|

WQP-150

|

150m3/h

|

14.0x3.0x2.5m

|

15.0kw

|

5.5kw

|

23.8kw

|

|

WQP-200

|

200m3/h

|

16.0x3.0x2.5m

|

18.5kw

|

5.5kw

|

27.1kw

|

I.Purify Landscape and River Water

separate the tiny suspended matter,alga and microscale of the flocs

2.Deep treatment of waste water

separate the microscale of the flocs

3.Petrochemical wastewater,Oil Recovery water,Biodiesel and Kitchen Wastewater

separate the oil and grease from waste water containing oil

4.Better quality of treated water,replace the secondary settling tank

5.Other industry waste water treatment,such as Breeding, slaughtering, spraying, electroplating, chemical pharmaceutical, paper making, printing and dyeing, tanning,fermentation, food and etc.

1. What is a DAF machine used for?

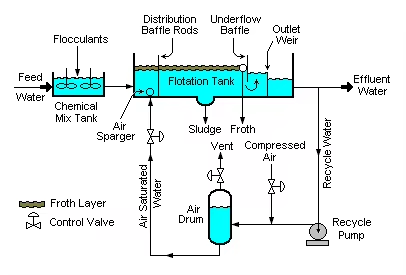

A DAF machine is used for water treatment, removing suspended solids, oils, and organic matter from wastewater. It works by releasing tiny air bubbles that attach to particles, making them float to the surface for removal.

2. How does a DAF machine differ from sedimentation?

DAF: Uses air bubbles to float particles up (for low-density solids like oils, fats, or flocculated matter).

Sedimentation: Relies on gravity to settle heavy particles down (suitable for high-density solids).

3. What are typical applications of DAF machines?

Industrial wastewater treatment (e.g., food & beverage, petroleum, textiles).

Municipal sewage treatment.

Oil-water separation.

Pre-treatment for reverse osmosis systems.

4. How to maintain a DAF machine?

Regularly clean the flotation tank and skimmer.

Check dissolved air pressure and nozzle blockages.

Inspect pumps, valves, and filters for wear.

Monitor chemical dosing systems (e.g., coagulants/flocculants).

5. What causes low removal efficiency in DAF?

Inadequate air dissolution (check pressure or compressor issues).

Improper chemical dosing (adjust coagulant/flocculant ratios).

High influent turbidity or temperature.

Clogged nozzles or damaged diffusers.

6. Can DAF handle high TSS (Total Suspended Solids) wastewater?

Yes, but pre-treatment (e.g., screening or pre-flocculation) may be needed for extremely high TSS levels to prevent nozzle blockages and optimize performance.

7. What is the typical energy consumption of a DAF machine?

Energy use varies by size, but a standard DAF system consumes ~0.3–0.8 kWh/m³ of wastewater, mainly for pumps and the air compressor.

8. How long does a DAF machine last?

With proper maintenance, DAF machines can last 10–15 years. Stainless steel components extend lifespan in corrosive environments.

9. Can DAF be used for drinking water treatment?

Yes, DAF is effective for removing algae, color, and organic matter in drinking water sources, often replacing traditional sedimentation tanks.

10. What’s the installation process for a DAF machine?

Level the foundation and connect pipes (inlet, outlet, sludge discharge).

Install the air dissolution system, tank, and skimmer.

Connect electrical components and control panels.

Commissioning includes water testing and parameter optimization.